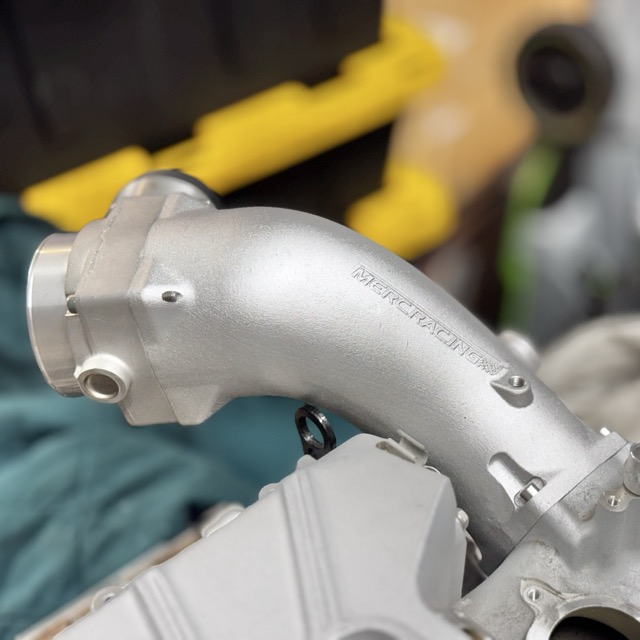

This page is to provide updates on the first production casting for the C7 longer intake tube that goes from 90mm to 80mm.

https://mercracing.net/shop/audi-3-0-tfsi-90mm-to-80mm-throttle-intake-upgrade/

As of Friday August 1st

Molds have been completed, and all issues have been corrected to allow the casting to take place. We experienced significant setbacks due to design changes, unmet needs, and unexpected delays, as some factories were unable to produce the product despite initial assurances. This added tremendous pressure and delays to the estimated timelines.

August 4th update:

This week, casting tests are being conducted and quality checks are being performed on the process. If all goes well, the production of the units will commence.

August 22 Update:

Casting company has finally completed the casting of the product and now working out the finalization of the parts. The factory asked for additional time as they had a temporary delay and also had safety inspections cause delays at their factory.

They sent me a photo showing the first casting and informed me that they are now working on the quality and CNC programming for the units. I asked for an approximate new ETA and am waiting for that update/ response.

Update August 29th

Production Castings have been completed. Now we wait for the processing and clean up of the castings, then on to CNC.

September 5th Update

Castings have been processed and cleaned off the extra molding process parts. The The factory was closed for a few days to observe a holiday period and is back in business this week. Waiting now for the CNC process and surface cleanup.

September 15th Update

Currently waiting in line for the the factory to process the CNC – Send message asking for possible ETA.

Septtember 29th Update

The current factory has been unable to perform the CNC work accurately. I had to decide to have them send the casts to a different factory that has the necessary skill set and equipment to handle the project’s requirements. In the photo below, you can see that they are having problems keeping the hole centered. This is totally unacceptable and cannot be utilized.

The factory that will be doing this work next has done other work for me that is more intricate and complex. They should be able to sort this out perfectly.

Initially, they are requesting permission to test one part first, and then they can provide a more accurate timeline for the CNC work completion.

October Update:

The factory failed to be able to properly complete the cnc work accurately. We attempted to have a separate factory take over the CNC but due to mistakes on the casting, the factory was unable to take on the work. This has forced me to find a new factory to make the product. The existing parts are with the original factory and currently working on redoing the work.

The current factory is now working on various ideas to mount and setup the CNC process accurately.

November 1

I have entered into a new contract with a different experienced factory. Once the molds are completed and progress starts, I will provide an accurate update. This has been an expensive and unprecedented experience. Really sorry this has happened and taken this long. Truly appreciate your patience and support.

November 13

Good news!! The factory has made progress and has figured out the CNC programming and now doing the batch and checks. Thanks for being so patient while we worked through this unexpected and long process.

November 24

First batch being processed for shipping. Being it’s a heavy shipment, this will take some time to arrive affordably. Waiting on confirmations and customs processing. Once they arrive to the USA, i will update here and give a more conclusive update. Hopefully, there are no issues, and they are done correctly.

I do have a backup factory working on this as well, just in case these have an issue. From the photos, it appears to be done correctly. Let’s see.

December 17th

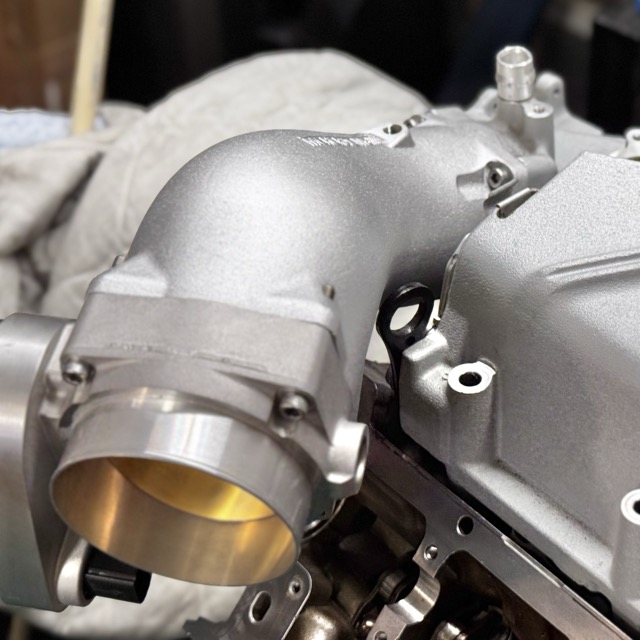

Great news! The units have arrived and the CNC work was done correctly. The parts need to be processed and cleaned before I can start shipping them out. They were handled by the factory multiple times and the units need final clean up and processing.

I have purchased tools to do the processing and clean up and will be working on these and start sending units out as I complete them.

Will post photos soon when I complete the final processing. Thanks to everyone who participated and your incredible patience while you waited for this to be handled for the first batch and pre-orders.

January 11th 2026

All Audi C7 intakes have been completed and shipped to the customers.

Photos of the finished product. These are now in stock and shipping.